Since we unveiled the first prototype of the Sion to the world on 27 July 2017, we have been sharing news with you about the development, design and, of course, construction of the next generations of the vehicle. Throughout the prototype phase, we have always sought your feedback and opinion – be it on test drives, through surveys or at a car clinic. This important phase has been completed since March. In the meantime, we are in the middle of one of the most exciting moments in vehicle development: the production of the series-validation vehicles.

We are supported in this by thyssenkrupp and Bertrandt, two very experienced partners who not only have extensive expertise in the field of automotive engineering, but also the necessary infrastructure and capacities to produce the series-validation vehicles quickly and to a high standard of quality.

As we have also given you insights into the construction of our SVC2 prototypes in 2020, we naturally don't want to leave you out of this important and unique process. On our social media channels, there have already been photos and information from the production process, however, today we have dedicated ourselves to the very important questions, which are perhaps particularly interesting for non-automotive-experts. What exactly is happening there? How is a series-validation vehicle assembled? And what happens next? Read the answers to these and other questions here.

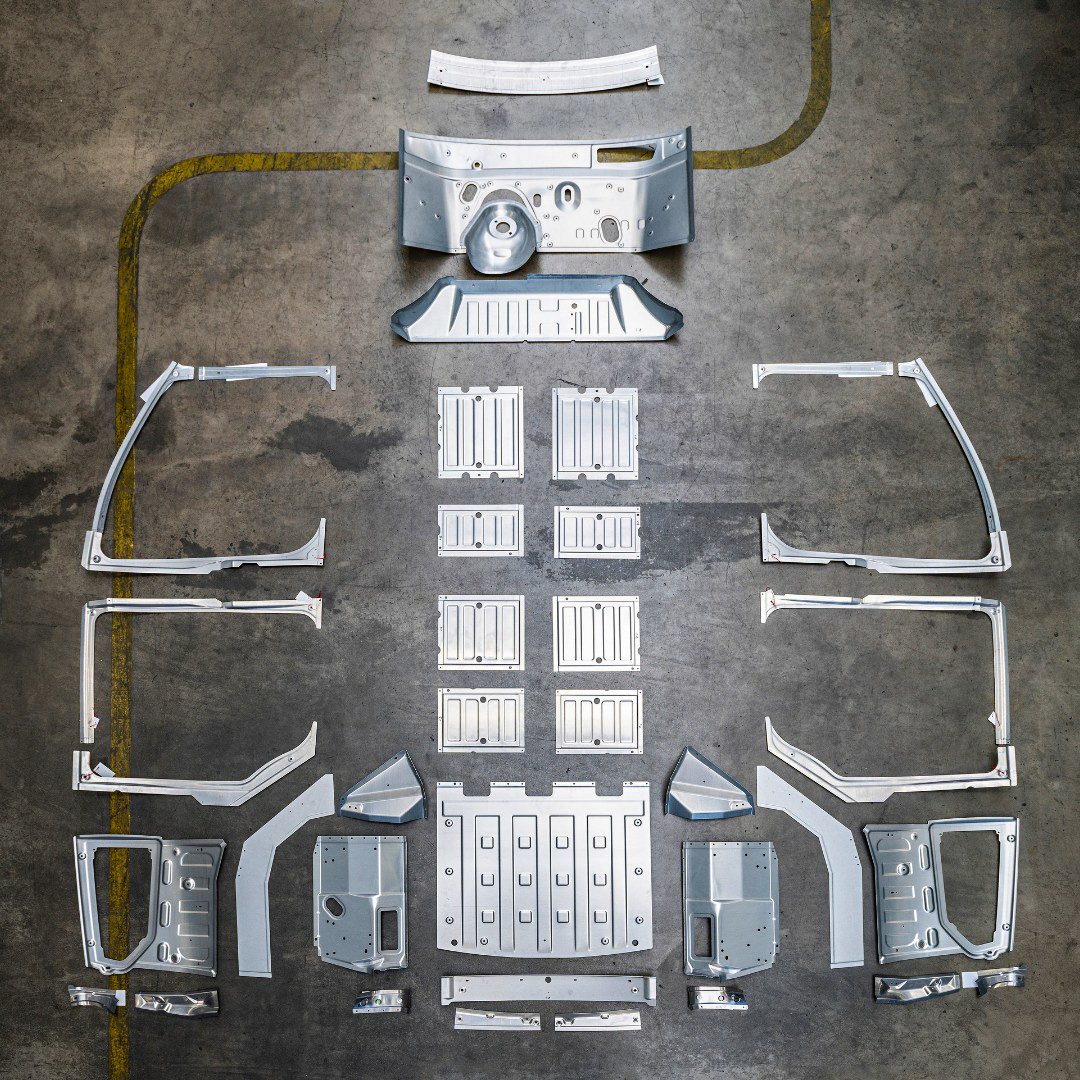

Kicking Things off With the Body in White

As an expert for integrated body construction solutions, thyssenkrupp Automotive Body Solutions is responsible for the production of the aluminium space frame. As a second step, Bertrandt takes over the assembly of the new Sion test fleet here in Munich. thyssenkrupp first manufactures the so-called body in white, i.e. the bodyshell of the vehicles. For this, all the required aluminium profiles, sheets and any other small aluminium parts needed are manufactured and then joined together.

Before assembly at Bertrand, the aluminum space frame gets a cathodic dip coating – a long-lasting corrosion protection. Later, the space frame will be covered with our solar body panels. Our motto? Solar instead of paint!

Let’s Start the Assembly

In total, the Sion consists of more than 1,500 parts. All of these components have to be brought together in the final assembly. This is where it also becomes clear whether and if so, which adjustments still have to be made in the construction before series production.

Every body in white has a VIN number, the Vehicle Identification Number. This number will accompany the vehicle from assembly through its entire life cycle and is an important identification feature for every car. Many of the following steps run in parallel before converging at a later stage.

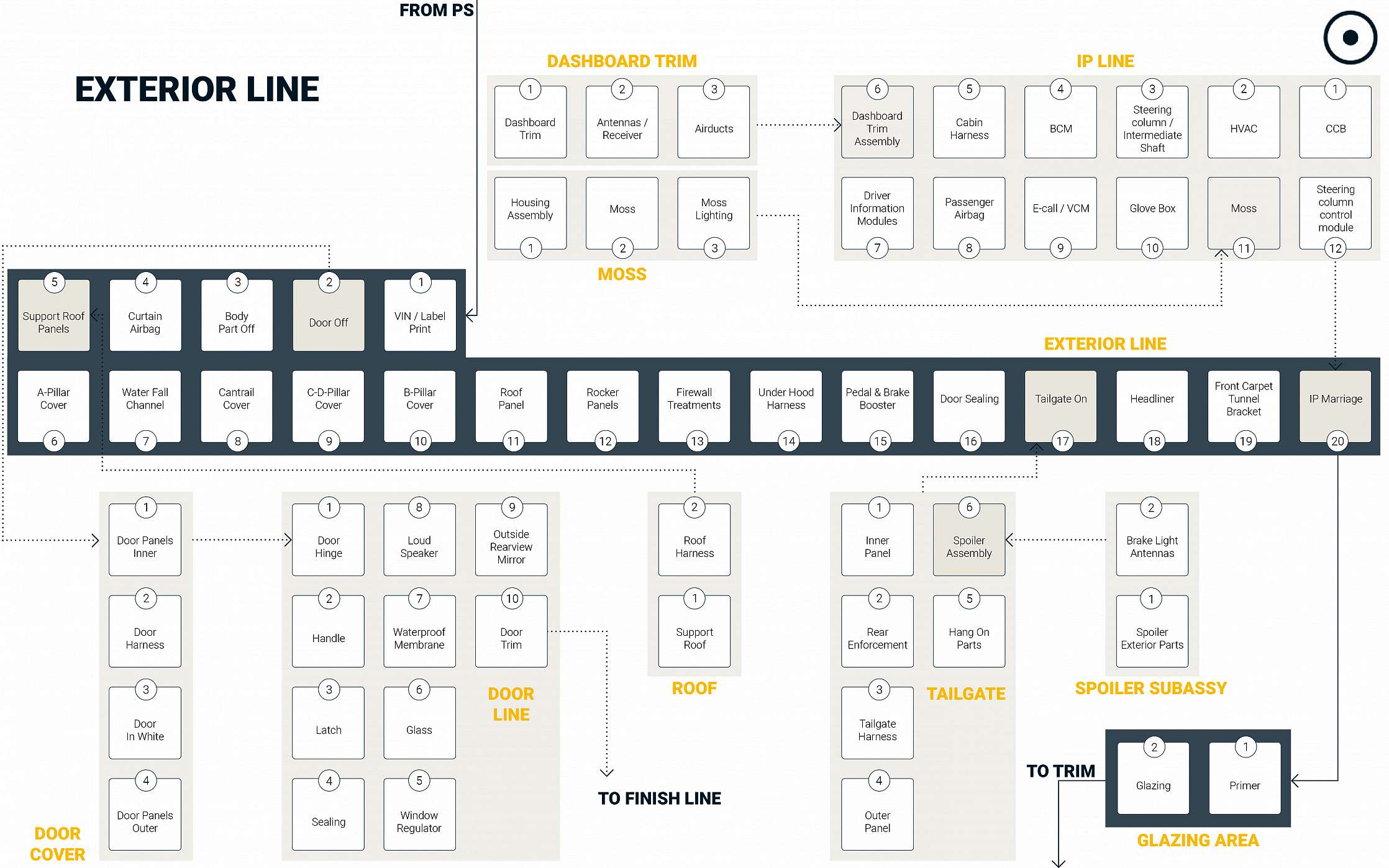

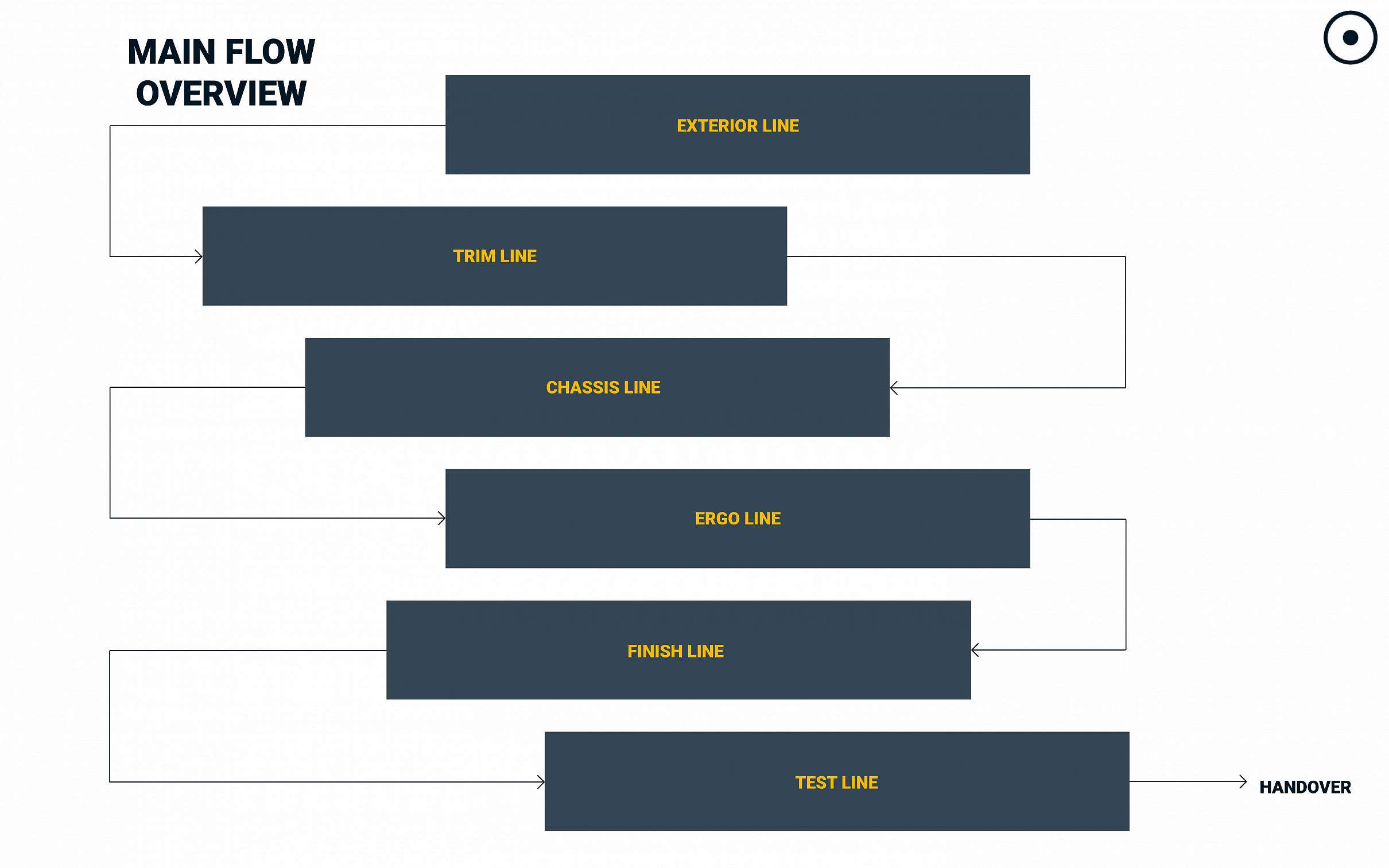

Assembly starts by removing all the movable components of the body in white, namely the doors, hood, and tailgate, and relocating them to pre-assembly areas specially prepared for this purpose. There they are given their solar integration, electrical integration, trim, insulation, and any necessary switches.

Assembling all these components reveals where improvements are still needed for series production. These adjustments then have to be transferred to series production. The exterior assembly line forms the leading assembly line on which all components are brought together step by step.

During this process, the wiring harness is also installed in the body in white. The wiring harness is the central nervous system of the vehicle's electrical architecture and connects all electrical components together. Their functionality is tested on a Yellow Board before integration into the vehicle. There, the engineers test whether everything has been manufactured correctly. With all the thousands of cables, small errors are bound to find their way into the wiring. Naturally, these must be eliminated before integration into the vehicle can commence. Only then turn signals, warning lights, and all associated switches are tested for proper function.

The integration of the wiring harness is followed by the assembly of the interior. In many different steps, the center console, carpets, headliner, seats, interior trim, as well as the dashboard are now integrated into the vehicle. The dashboard is also assembled in a separate assembly area. It is then integrated and installed as a unit. The major areas of focus here are the air ducts, the instrument cluster, the infotainment, and, of course, the moss.

Next? Catching the Drivetrain!

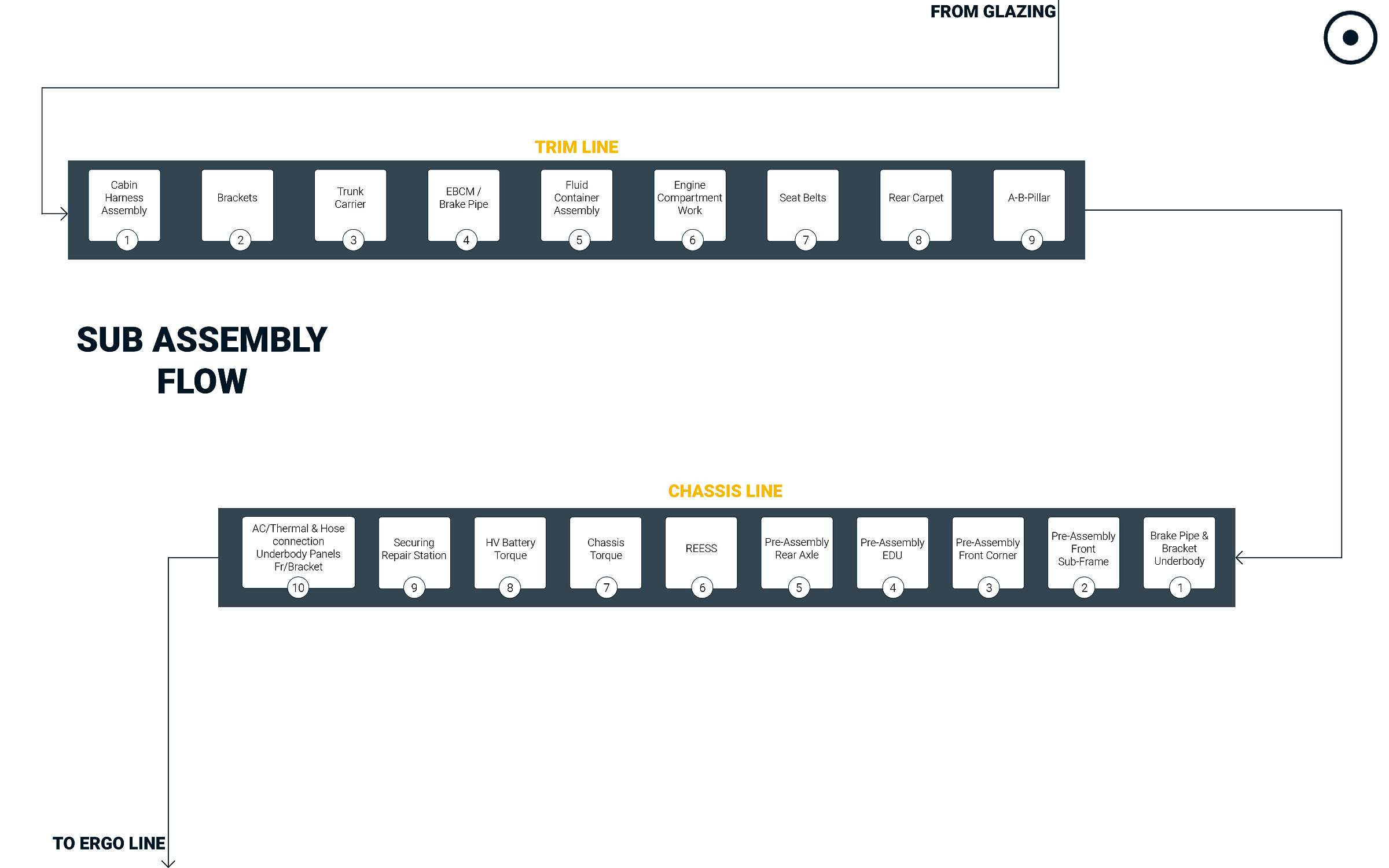

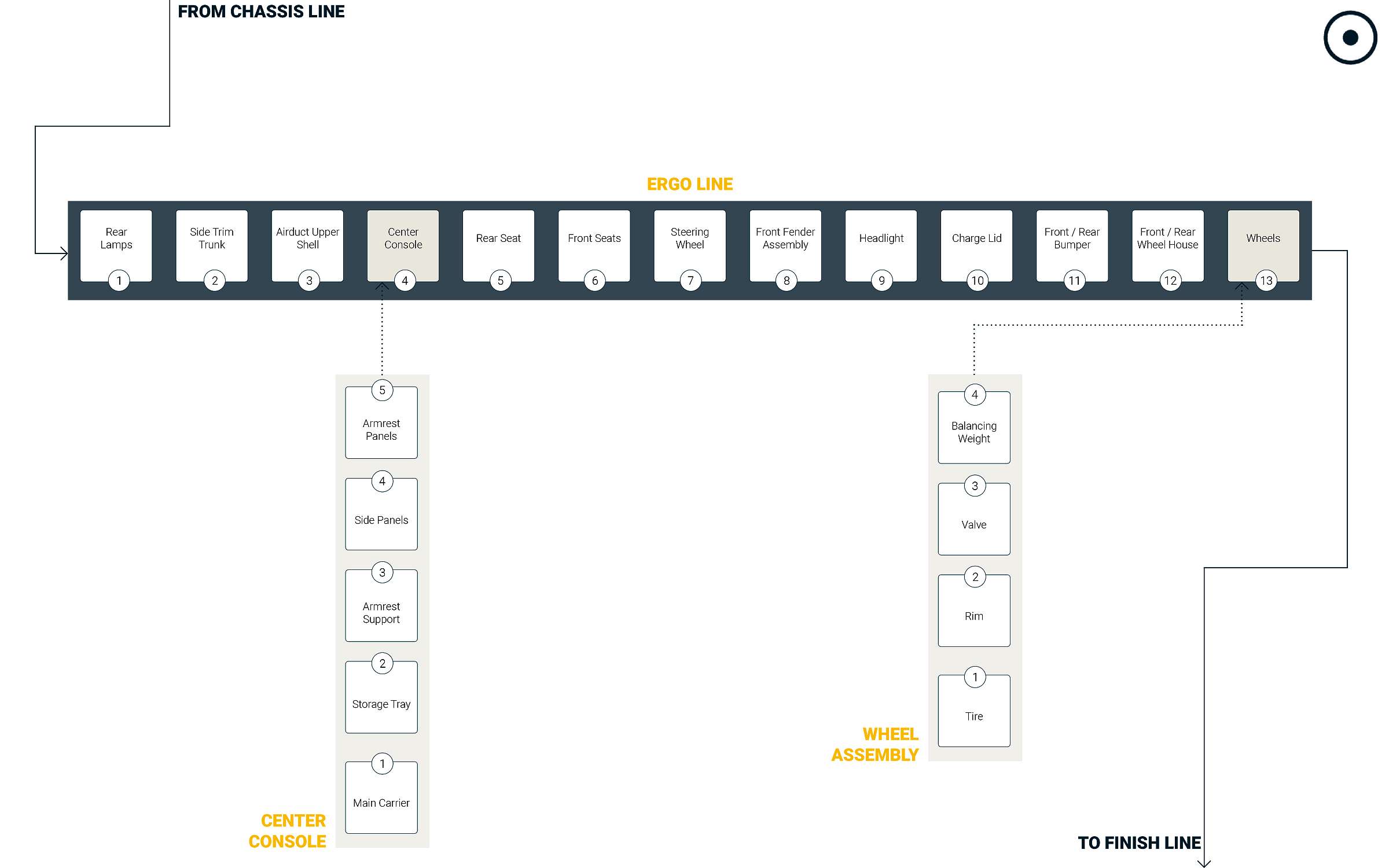

Needless to say, the heart of every car is the drivetrain. For the Sion’s chassis, various heavy components are brought together in the dedicated assembly area. The chassis is a complex composite consisting of springs, dampers, as well as rims with tires, rubber mounts, steering, stabilizers, and brakes. The electric motor is located in the front area of the bottom section. It is firmly mounted in a solid bracket specially provided for this purpose. This is where the electric propulsion will later be transmitted to the front axle.

The bidirectional charger is also mounted in the front part of the vehicle and enables, among other things, charging of the battery. Probably the heaviest component is the high-voltage battery located between the front and rear axles. This component is also assembled in a designated area. This requires not only the utmost concentration but also the support of several lifting devices. After all, a battery like this weighs about 360 kg.

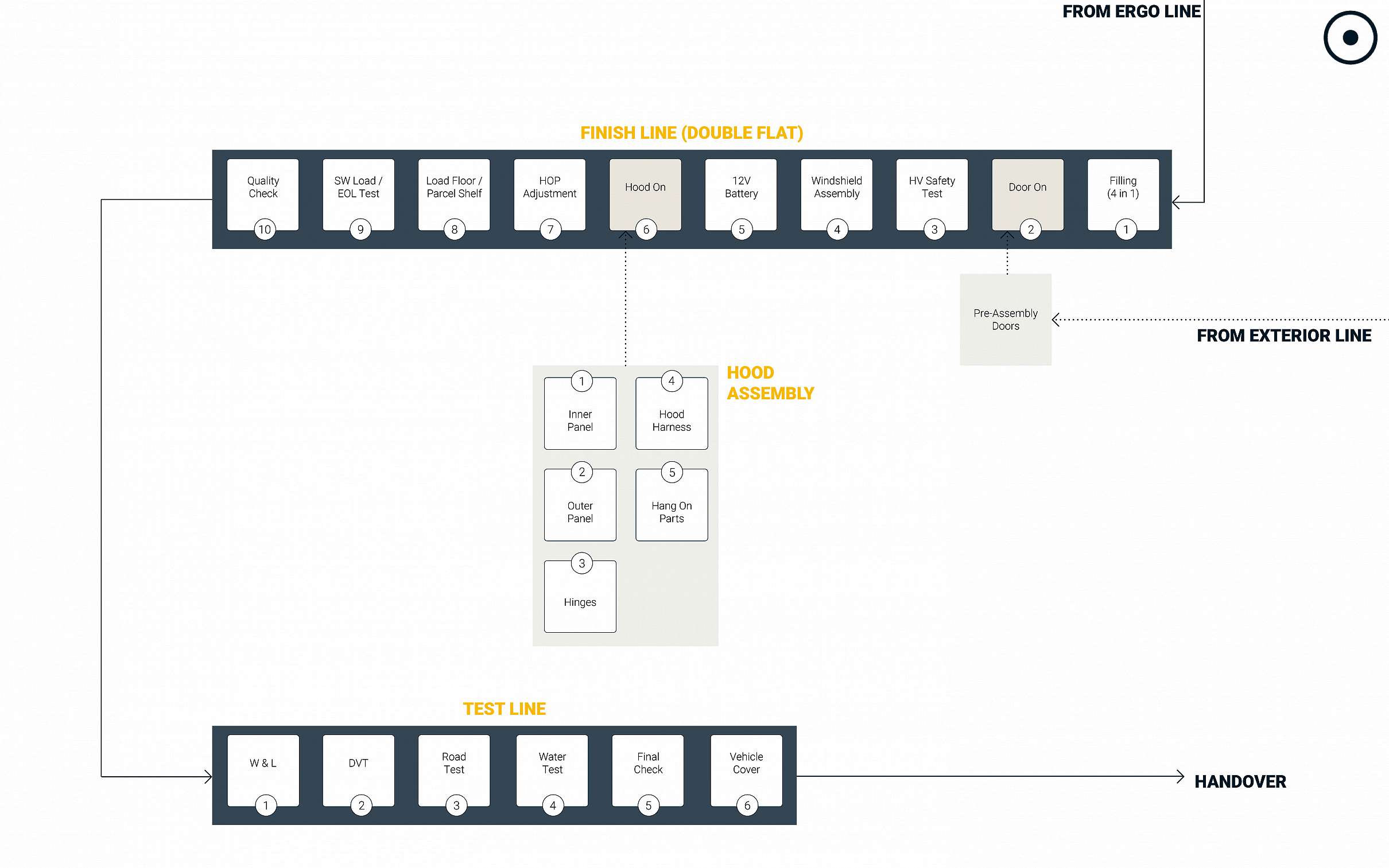

Next, the various components of the chassis, i.e. the axles, the e-machine, and the drivetrain, are mounted on the body and merged with it – probably the most important step in the complex assembly of a validation vehicle. On the home stretch, the tailgate, doors, and hood are then reattached to the vehicle. To ensure that the vehicle is always fully accessible throughout the entire process, this happens at the very end.

Are we there yet?

Although the assembly of the series-validation vehicles is completed, the vehicle production process is not. In a final, but very important step, the so-called commissioning takes place. Now the vehicle is brought to life for the first time. The electrical systems are activated and the control units are "flashed" with the software. All these units as well as the electrical components are checked for functionality step by step. At this point, all the hard work pays off. Something that has never been assembled before takes on its final form and can be moved for the first time.

Assembly is an intensive and highly complex process involving a total of hundreds of people - whether in preparation, in research and development, or in the production itself. We would also like to take this opportunity to thank all the people for their great work in making this major and important step towards series production of the Sion possible.

Over the coming weeks and months, we will produce a total of 16 complete vehicles and 21 test structures. We will be undertaking testing, validation, and certification of the Sion until it rolls off the production line in Finland. These will include uncompromising practical tests under extreme conditions, optimizing our solar technology, as well as refining driving dynamics on test tracks and on public roads in addition to crash tests. We are therefore looking forward to a more than exciting journey, on which we would like to invite you. So keep checking back, it's worth it!

P.S. The first solar panels for our series validation vehicles have arrived. Engineer Dominik and Community Representative Sebastian discuss texture and materials, as well as the challenges we faced during development. Overall, we were able to integrate more cells than before. How we managed to do that? Check out this video!